Comparing Manual vs. Automatic Strapping Machine Options for Efficiency

Comparing Manual vs. Automatic Strapping Machine Options for Efficiency

Blog Article

Releasing the Possible of a Strapping Equipment in Streamlining Your Procedures

A strapping equipment could be the solution you have actually been browsing for if you're looking to improve your packaging efficiency. These machines can lessen manual labor while guaranteeing your products are securely packaged. With various options offered, discovering the ideal fit for your procedures is important. Exactly how do you choose the best one, and what benefits can you really expect? Allow's discover the possibilities with each other.

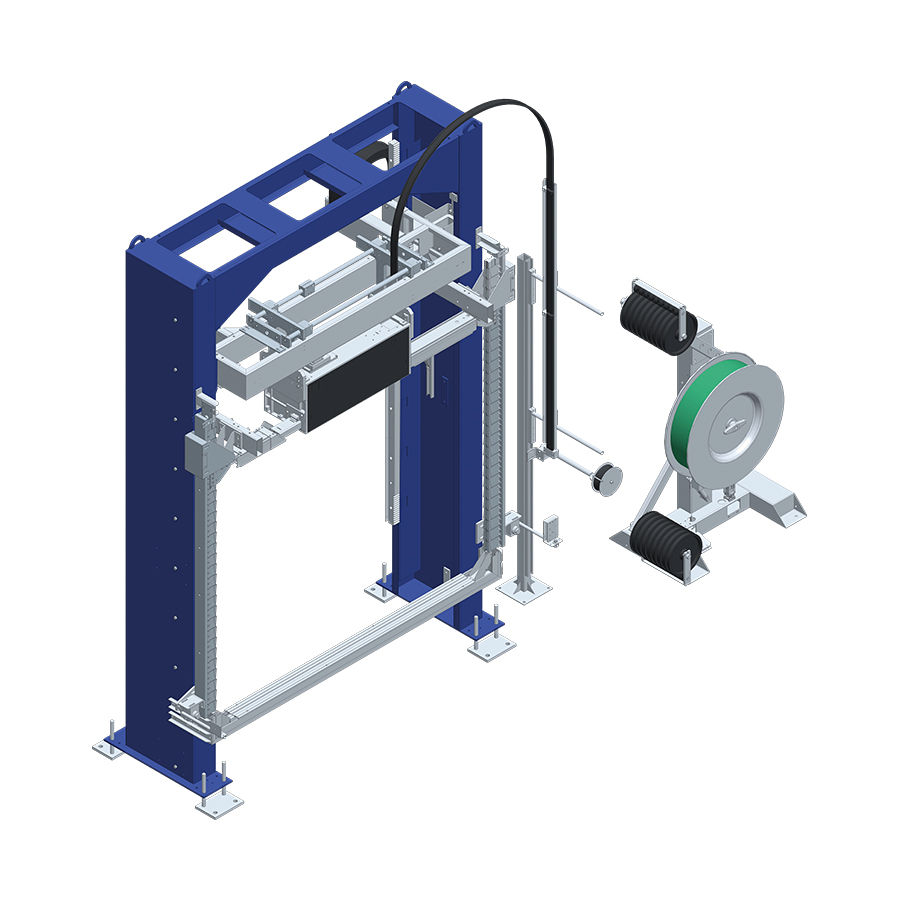

Understanding the Essentials of Strapping Machines

Strapping equipments are crucial devices in product packaging and logistics, made to safeguard things for secure transportation. These machines utilize numerous materials, like polypropylene or polyester straps, to pack products with each other (Strapping Machine). You'll find that strapping devices come in various types, consisting of manual, semi-automatic, and fully automated versions, each fit for certain functional needs.Understanding exactly how these machines work is important for optimizing your process. They apply stress to the band before sealing it, making sure a tight fit that keeps your products secure throughout handling and shipping. Acquainting yourself with the parts, such as the tensioning system and sealing method, can help you pick the ideal machine for your business

Secret Benefits of Utilizing a Strapping Equipment

When you purchase a strapping device, you're not simply boosting your product packaging procedure; you're also boosting efficiency and reliability. These machines allow for quicker strapping, reducing manual work and minimizing the danger of errors. You'll see a significant reduction in time spent on product packaging, enabling your group to focus on various other essential tasks.Moreover, strapping makers supply consistent stress and safe and secure plans, which assists stop damage throughout transportation. This reliability leads to fewer returns and boosted customer satisfaction. Furthermore, using a strapping device can save you cash in the future by lowering product waste and lowering labor costs.Lastly, they're functional adequate to deal with different plan sizes and products, making them a useful asset in any procedure. Welcoming a strapping machine indicates you're purchasing an extra streamlined, efficient, and effective strategy to product packaging.

Types of Strapping Machines Available

You have actually obtained options when it comes to strapping devices. You can pick between manual strapping machines for hands-on control or automatic strapping systems for effectiveness. Each kind has its own benefits, making it vital to pick the right one for your needs.

Manual Strapping Machines

Although many packaging options exist, hands-on strapping devices stick out for their simpleness and performance. These devices are best for tiny to medium-sized procedures where transportability and flexibility are key. You'll discover them easy to utilize, needing very little training. With a hands-on strapping equipment, you can quickly secure bundles utilizing polypropylene or polyester straps, guaranteeing your products remain undamaged throughout shipping.They supply a cost-efficient solution without sacrificing quality, making them optimal for companies on a budget plan. Plus, manual strapping devices are small and can fit in limited rooms, permitting you to improve your operations. Whether you remain in a stockroom or a little workshop, these machines can substantially enhance your packaging procedure, making your procedures more reliable and reliable.

Automatic Strapping Solutions

Have you taken into consideration how automatic strapping systems can revolutionize your product packaging operations? These equipments provide effectiveness and precision that hand-operated approaches merely can't match. With options like totally automated, semi-automatic, and high-speed strapping systems, you can choose the ideal suitable for your production needs. Fully automated systems streamline the whole procedure, requiring minimal operator treatment. Semi-automatic makers, while still effective, enable for a bit extra control. High-speed systems accommodate high-volume procedures, guaranteeing quick and dependable strapping. By integrating these systems, you'll not just lower labor costs yet likewise enhance product packaging top quality. Say bye-bye to inconsistent strapping and hey there to uniform, safe plans that enhance your operational efficiency and speed. It's time to tip up your video game with automatic strapping options!

Elements to Take Into Consideration When Selecting a Strapping Maker

Choosing the right strapping device can greatly boost your product packaging effectiveness, so it's vital to take into consideration numerous crucial factors prior to choosing. Initially, consider the type of products you'll be strapping. Different machines are created for plastic, steel, or paper strapping, so pick one that meets your needs.Next, consider the speed and quantity of your operations - Strapping Machine. If you're dealing with high volumes, an automated strapping machine may be preferable, while a hand-operated alternative could be enough for smaller sized tasks.Don' t fail to remember about the machine's dimension and impact. Make certain it fits your work area without hindering movement.Additionally, try to find features like adjustable stress and sealing methods to advertise convenience. Review your budget, balancing upfront costs versus lasting effectiveness gains. By thinking about these variables, you'll make a much more enlightened choice that straightens with your operational goals

Exactly how to Integrate a Strapping Maker Into Your Workflow

To successfully incorporate a strapping machine right into your operations, start by reviewing your functional needs. This helps assure the this article device fits flawlessly right into your existing procedures. Once that's set, reliable personnel training will be vital to maximizing its efficiency and efficiency.

Examining Functional Needs

Incorporating a strapping equipment right into your process can significantly improve performance and productivity. Evaluate your current packaging process. Identify traffic jams where manual strapping slows you down. Consider the quantity of products you manage everyday and the particular requirements for securing those products. Assess the physical area offered for the machine to assure it fits flawlessly right into your operation. Next off, establish the sorts of products you utilize for strapping, as the maker ought to fit them. It's likewise crucial to consider how the maker will connect with existing tools and operations. By understanding these operational needs, you can choose the ideal strapping device that lines up with your objectives, inevitably causing smoother procedures and improved output.

Training Personnel Efficiently

While the intro of a strapping equipment can improve your workflow, effective training for your personnel is essential to optimize its benefits. Start by supplying hands-on demos to acquaint everybody with the device's functions and functions. Encourage your group to ask questions and share their concerns. Produce an easy to use manual or anchor quick-reference overview to enhance training and serve as a resource. Schedule routine correspondence course to keep skills sharp and deal with any kind of changes or updates. In addition, designate an advisor or knowledgeable operator to support brand-new employee as they adapt. By purchasing your personnel's training, you'll not only increase their self-confidence but likewise boost performance, ensuring the strapping equipment comes to be an essential part of your procedures.

Upkeep Tips for Optimum Strapping Machine Efficiency

Preserving your strapping device is crucial for ensuring consistent efficiency and durability. Start by consistently inspecting and tightening any type of loosened bolts or screws to prevent resonances that can trigger wear in time. Clean the maker daily, eliminating dirt and debris that can affect its performance. Lube moving components as suggested in the producer's manual, making sure smooth procedure and decreasing friction.Monitor the strapping stress and adjust it according to your material requirements, as inappropriate tension can cause item damages or thrown away products. Strapping Machine. Additionally, examine the strapping material for any kind of signs of wear or damages, changing it as required to avoid interruptions in your workflow.Finally, timetable regular expert maintenance to capture possible issues prior to they end up being significant troubles. By following these upkeep suggestions, you'll maintain your strapping equipment running smoothly, boosting your operations and lengthening its lifespan

Real-World Success Stories of Strapping Equipment Implementation

After ensuring your strapping equipment runs successfully, it's time to check out how businesses have efficiently utilized this innovation. Take, for example, a packaging business that fought with irregular strapping. After implementing a modern-day strapping equipment, they saw a 30% boost in throughput and a significant reduction in material waste.In one more instance, a furnishings manufacturer made use of strapping machines to protect items for shipping. This not only quickened their packing procedure however likewise lowered damage throughout transportation, leading to happier customers.Similarly, an ecommerce service integrated strapping devices into their procedures, permitting them to effectively bundle products and decrease labor costs.These success tales highlight how purchasing a strapping machine can dramatically boost your operational efficiency, cut expenses, and improve customer satisfaction. By learning from these instances, you can better picture just how this technology can change your own organization processes.

Regularly Asked Inquiries

Can a Strapping Equipment Manage Various Products and Sizes?

Yes, a strapping equipment can handle numerous products and sizes. You'll discover versions created to suit various band widths and densities, making sure convenience for your packaging needs and boosting performance in your procedures.

What Is the Ordinary Life Expectancy of a Strapping Maker?

The average lifespan of a strapping maker commonly ranges from 5 to 10 years, depending on use and upkeep. Routine maintenance and correct care can assist you maximize its resilience and efficiency over time.

Are There Safety Functions in Modern Strapping Machines?

Yes, modern-day strapping equipments included various click this link security functions, like emergency situation quit switches, safety guards, and sensors that protect against operation when parts are incorrectly positioned. These enhancements assist ensure your security while utilizing the devices.

Just How Much Training Is Required for Operators?

You'll need very little training for drivers, typically a couple of hours to a number of days, relying on their experience. Most makers include straightforward user interfaces, making it easy for your team to adjust swiftly.

Can Strapping Machines Be Leased As Opposed To Bought?

Yes, you can rent strapping makers rather than purchasing them. Leasing commonly supplies versatility, minimizing in advance costs while allowing you to update tools as required. It's a wise alternative for managing your operational budget plan effectively. You'll locate that strapping machines come in various types, consisting of handbook, semi-automatic, and totally automated versions, each suited for specific functional needs.Understanding just how these machines work is essential for maximizing your operations. When you invest in a strapping device, you're not simply boosting your product packaging procedure; you're also improving effectiveness and integrity. You can select between manual strapping devices for hands-on control or automatic strapping systems for effectiveness. If you're working with high quantities, an automatic strapping machine might be more ideal, while a hands-on choice can be adequate for smaller sized tasks.Don' t fail to remember regarding the maker's dimension and footprint. After implementing a modern-day strapping maker, they saw a 30% increase in throughput and a substantial reduction in material waste.In another instance, a furniture manufacturer utilized strapping devices to protect items for shipping.

Report this page